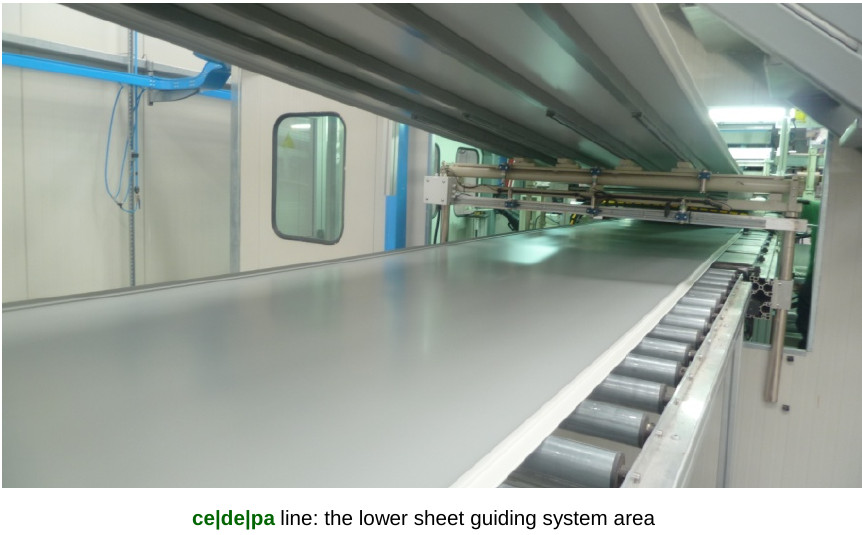

ce|de|pa is the first and largest research centre for the development of manufacturing processes for insulating panels. A unique, cutting-edge facility entirely devoted to experimenting and prototyping on an industrial scale, designed to allow the building industry on a worldwide scale to accelerate the development of new solutions to make polyurethane panels for thermal insulation with the specific continuous dual lamination process technology.

Gruppo Manni spa based in Verona is one of the main figureheads in the world of Italian entrepreneurial excellence. It has more than 900 employees, 20 production, service and distribution centres in Italy and abroad. Led by Francesco Manni and his father Giovanni, it has a 500m euro turnover. Manni spa's products represent a less flashy form of Italian manufacturing compared to fashion and design and yet they are equally important and successful. One of the most prominent examples few know about: 70% of the steel structures with which Rho's trade fair centre of Milan was built and more than 50% of those for Expo 2015, including the areas for Italy and the US, come from Gruppo Manni’s plants.

Gruppo Manni has a long-standing entrepreneurial history. A corporate venture started in 1945 Francesco Manni enthusiastically told us by tracing the main events, thereby providing a valuable lesson about resisting against the worst economic crisis from the post-war period up until today.

All for one, one for all.

Over the years the Manni family, who still has full ownership of the group and manages the company directly, was able to diversify its business and structure its offer in an innovative way with an increasing focus on the client's needs. The group is currently structured around three main business units. The first one, which represents its origins, is the steel service centres, “a solution that recalls Lego or Meccano models,” says Francesco Manni, “we provide the client with all the pieces, ready to be assembled in order to skip the work in the workshop”. The second macro area is that of insulating polyurethane panels for roofings and walls, with a high isothermal coefficient and used to build industrial and civil prefabricated buildings. By integrating these two production areas, Manni can provide clients with a comprehensive and beneficial offer. Its third business unit, the most recent one, is devoted to making systems to generate energy from renewable sources, such as photovoltaic, wind and biogas sources. Thanks to the partnership with Turin's polytechnic, the group is also specialising in making hydroelectric system that can make the most of the differences in level of extremely model waterways.

A family, a company, a number of successful ideas.

It was 70 years ago when Luigi Manni set up as a sole trader to sell reclaimed iron and steel products for use in the building industry. “We started out as pure traders", says Francesco Manni. After the company's expansion in the 1960s led by Giuseppe Manni, there was an important turning point in the 1970s. “My father came up with the idea of a service centre designed not only for flat products, which already existed in other countries, but designs and makes it also for long products such as beams, U-shaped instruments and construction steel”. At the time it was a revolutionary idea that became an instant success in the industrial building and infrastructure world. Indeed, products that before were just niche products could be easily used and costs were reduced, which promoted and considerably extended the use of steel in this kind of construction. A model that many will follow in subsequent years, though Manni is still a global leader with more than 400,000 tonnes a year of steel processed and sold. “1989 marked another milestone in the group's history,” says Francesco Manni, “the acquisition of Isopan.” The factory, which is still based in Frosinone, belonged to the Brollo family from Milan. Francesco and his father, Giuseppe, decided to first buy a majority stake and then the whole company. Another successful idea: thanks to this operation, Gruppo Manni can offer clients not just the metal components forming the frame of a structure, but also the outer covering with its panels: "panels are light and easy to carry," says Francesco Manni, "unlike other products we make, panels are the one that gave us the greatest satisfaction abroad, as it is a finished, complete product. It features a very clear trademark and also users can immediately associate it with a specific manufacturer. There is basically a direct link between us and the client through the 'brand'". "We must not then forget – Mr. Manni says – that panels were entirely invented in Italy. Together with our competitors, we have the most sophisticated and high performance know how on a global scale for this kind of production."

Internationalisation.

Either by choice or by need, Manni group has always been able to also look beyond domestic borders. The core of the company, the key production was and remains in Italy, though the company has long set up a number of plants abroad. The internationalisation process was initiated precisely with the entry in the panel sector. Indeed, in 2001 the company decided to boost its manufacturing capacity and presence on foreign markets by building a plant in Barcelona, Spain. In 2007 the company also opened a factory in Romania near the capital, Bucharest, and in 2012 it set up a plant in Germany as well. However, its conquest of foreign markets continued. It will soon start making panels in Russia, while within 2015 it will inaugurate a new manufacturing site in Mexico. The group's international vocation also involves the creation of energy systems from renewable sources, as shown by the important investments in the photovoltaic sector in Morocco.

Targeted research to fight the crisis: ce|de|pa's contribution.

Francesco Manni has very few doubts about the road to follow to overcome one of the toughest times Italy has ever experienced from an economic point of view. A crisis that considerably affected the building industry as well. “The only way to overcome the crisis is to innovate and increasingly look for products that are better than existing ones. A tool like ce|de|pa allows operators like us to move forward by testing the limits of new technologies to achieve top results. Together with my staff, we became immediately aware of the contribution this centre could offer: a place to develop research targeted and designed around market needs. Clients ask us for products that offer something extra and ce|de|pa provides the conditions to be able to offer it.”

“As for the metalworking front and namely the standards associated with the panel coating material and individual panel processing stages (e.g. cutting, profiling) – says Francesco Manni – research has not raised the bar in terms of production to levels that are so high that only marginal aspects can be improved. Containment costs have now reached excellent results both in terms of quality and manufacturing procedures. Polyurethane foams instead still provide large room for innovation. Namely, in terms of fire resistance, where there are increasingly strict regulations and rock wool panels still provide the best performance, research can really move forward. The price/quality ratio is still essential, especially for products intended for prefabricated buildings, where low costs are still a crucial factor.”

Challenges lying ahead.

Prefabricated panels are widely used for industrial buildings, while up until today there has been a more limited use of them in residential building. Usually other materials are chosen to make living areas that are cost-effective, though this is not a prevailing aspect like in other kinds of buildings. Said materials are commonly regarded as more comfortable and aesthetically pleasing (for instance wood), though polyurethane panels have definitely higher technical performance levels compared to the levels of other materials. Mr. Manni adds, “I hope that research will also focus on this aspect and will soon be able to bridge this gap; I think it could be a new frontier.”

Just one international certification process. A dream?

"Finding your way through the jungle of regulations and bodies of various countries is a task in itself", underlines Francesco Manni. “To certify the quality of a panel, each country has its own institute, its own rules, its own red tape. The procedure changes from the US to Switzerland, but also inside the EU itself each country has its own rules like Germany, France, Spain, but also Poland, Hungary and the Czech Republic. Hence, panel manufacturers must increase costs and time to fulfil requirements to obtain countless certifications for the same product.” ce|de|pa has joined a European network of panel certifying labs designed to provide a sort of pre-certification for panels. "This is an excellent first step towards a certification applying at least across the whole of Europe and that will hopefully expand across international markets as well”, Manni concluded.

Open Attachment